BB-H-886E

4.2 Quality conformance inspection.

4.2.1 Tests and examinations. Perform the content and capacity tests, and examinations of

table II. Any defects in the content or capacity tests shall be cause for rejection of the lot. A lot

for testing the content and capacity shall be defined as the number of containers filled from the

same source during an uninterrupted filling sequence and offered for examination at one time.

Any defects found in the examinations of the containers shall be cause for the rejection of only

those defective containers.

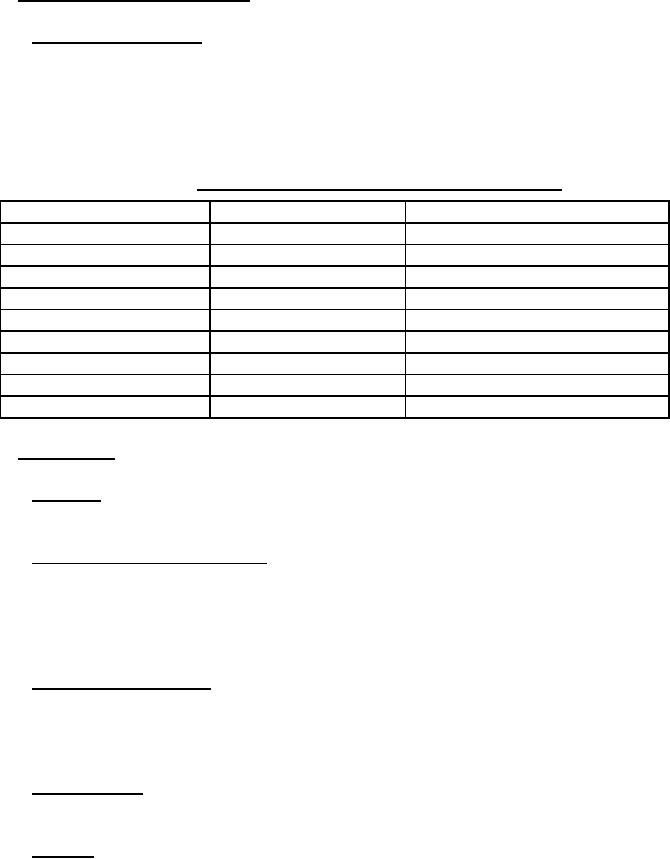

TABLE II. Tests and examinations of preparation for delivery.

Test/Examinations

Defect

Inspection level

Content

Not as specified in 3.1

One sample per lot, as per 4.2.1

Container

Not as specified in 3.2

100%

Paint

Not as specified in 3.2.1

100%

Maintenance

Not as specified in 3.3

100%

Leakage

Not as specified in 3.4

100%

Capacity

Not as specified in 3.5

One sample per lot, as per 4.2.1

Workmanship

Not as specified in 3.6

100%

Marking on container

Not as specified in 5.1

100%

Packaging and packing

Not as specified in 5.2

100%

4.3 Test methods.

4.3.1 Sampling. Samples for testing the content and capacity in table II shall be from filled

containers and shall be one sample unit per lot.

4.3.2 Hydrogen content determination. Hydrogen content shall be determined in accordance

with the analytical procedures specified by CGA G-5.3. The minimum hydrogen content shall

be 99.95 percent for grade A, 99.99 percent for grade B, and 99.999 percent for grade C.

Otherwise, compliance with the minimum requirements has not been met and shall constitute

failure of this test.

4.3.3 Impurities determination. The sample shall be analyzed for the impurities listed as

limiting characteristics in CGA G-5.3 using the analytical procedures specified therein. Unless

otherwise specified in the contract or purchase order (see 6.2), these impurities shall not exceed

the maximum quantity specified for the appropriate QVL.

4.3.4 Documentation. Records of the analysis and the qualifying concentrations used must be

kept on file for two years, and available upon the government's request.

4.3.5 Leakage. Each cylinder, after filling, shall be tested for leakage by applying a soap

solution to all portions of the valve, the junction of the valve and cylinder, and the safety device

on the cylinder. Care shall be taken to ensure that the solution used does not contaminate the

valve outlet. Any evidence of gas leakage, as evidenced by bubbling of the soap solution, shall

constitute failure of this test. Failure of this test shall be cause for rejection of the cylinder.

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business