MIL-DTL-38741A

b. Attach a septum to the cylinder and chill the base of the cylinder in liquid nitrogen for 15

minutes. Do not purge the cylinder when attaching the septum as this would alter the relationship

between the bromochlorodifluoromethane and the contaminants. Instead, the small amount of air

behind the septum is permitted to enter the standard when the valve is opened.

c. After verifying that the septum is still attached securely, open the valve. Keep the cylinder

in liquid nitrogen.

d. Using appropriately sized syringes, individually and in turn add the gaseous contaminants

listed in table III in the amount indicated. The indicated vapor densities are based on a laboratory

temperature of 20.0 °C and a barometric pressure of 100.0 kPa. These data must be adjusted to

reflect actual laboratory conditions.

e. Using an appropriately sized syringe, add the liquid contaminant listed in table III in the

amount indicated. For best accuracy, this contaminant and its syringe should be pre-chilled in a

freezer (approximately -20 °C) and promptly transferred. The indicated liquid density is based on

available manufacturer data and is approximate due to the absence of practical temperature

control.

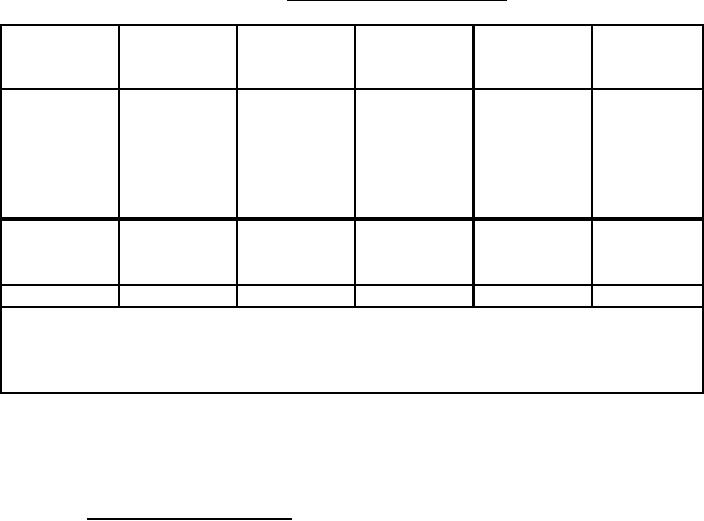

TABLE III. Calibration standard impurities.

Vapor

Volume

mg

mg/kg

Total mg/kg

Present3

1

2

Component

Density,

Added,

Added

Added

mg/mL

mL

HFC-23

2.895

3.9

11.3

CFC-13

4.331

2.6

11.3

HCFC-22

3.606

3.2

11.5

Halon 1301

6.288

1.8

11.3

Halon 1201

5.355

2.1

11.2

CFC-12

5.077

2.2

11.2

Liquid

Volume

mg

mg/kg

Total mg/kg

Added1

Added2

Present3

Component

Density,

Added,

mg/µL

µL

Halon 1202

2.463

4.6

11.3

1

If necessary, correct mg added for the purity of the calibration component.

2

Values are determined during preparation of standard.

3

Column to be filled in, (see 4.4.1.5), after determining ppm present in stock components

(see 6.3).

f. Close the valve and allow the calibration standard cylinder to return to ambient

temperature. Set the cylinder aside for a minimum of 12 hours to allow all the cylinder's contents

to equilibrate.

4.4.1.5 Calibration standard analysis.

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business