MIL-PRF-27210J

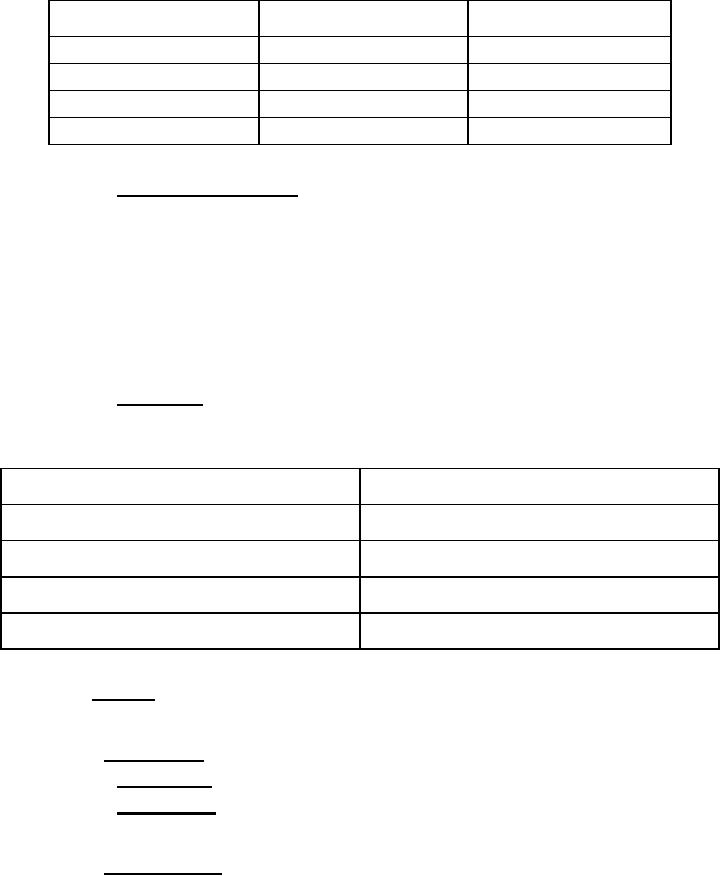

TABLE III. Individual inspection

TEST

TYPE I

TYPE II

Leak test

4.4.2

---

Odor test

---

4.5

Purity test

---

4.5

Moisture test

---

4.5

4.2.3.3 Sampling inspection per lot. Randomly selected samples of Type I oxygen as specified

in Table IV shall be subjected to the following inspection:

Odor test

4.5

Fill pressure

4.4.1

Purity

4.5

Moisture

4.5

The fill pressure shall be performed prior to the odor, purity, and moisture tests. The cylinder pressure

shall be checked after completion of all tests. If the sample cylinder pressure is below the minimum

acceptable value, the cylinder shall be filled to within the acceptable range.

4.2.3.4 Lot definition. Each set of Type I oxygen cylinders filled on the same manifold at the

same time shall constitute a lot.

TABLE IV. Sampling for test

Number of containers in lot

Number of containers to be sampled

1

1

2 - 40

2

41 70

3

71 - over

4

4.3 Sampling. Samples required by 4.2.1 and 4.2.2 shall be delivered to the designated

Government Laboratory (see 6.4), another designated laboratory, or other laboratories authorized by

AFPA/PTPT, 2430 C Street, Bldg 70, Area B, Wright-Patterson AFB OH 45433-7632.

4.3.1 Sampling point. The sampling point will be as follows:

4.3.1.1 Type I oxygen. Samples shall be taken from the manifold during filling operations.

4.3.1.2 Type II oxygen. Samples shall be taken from Type II oxygen storage tanks at the

manufacturing site or any distribution facilities. If a distribution facility is supplied from more than one

storage or manufacturing facility, each facility shall be checked as specified above.

4.3.2 Sampling method. Unless otherwise specified (see 6.2), oxygen shall be sampled

according to the methods of Table V. Sample size shall be sufficient to provide the analyzer with 7 liters

of oxygen at 10 atmospheres of pressure.

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business