MIL-PRF-27210J

4.3.2.1 Sample identification. The following data shall be provided on each sample sent to a

Government laboratory for analysis: Item name, specification number, Type (I or II), sample number,

sampler serial number, contractor's name, address, phone number and return shipping address for

sampler, Government representative's name, address, and phone number, reason for analysis (first

article, periodic, or resample), contract number, and date sample taken.

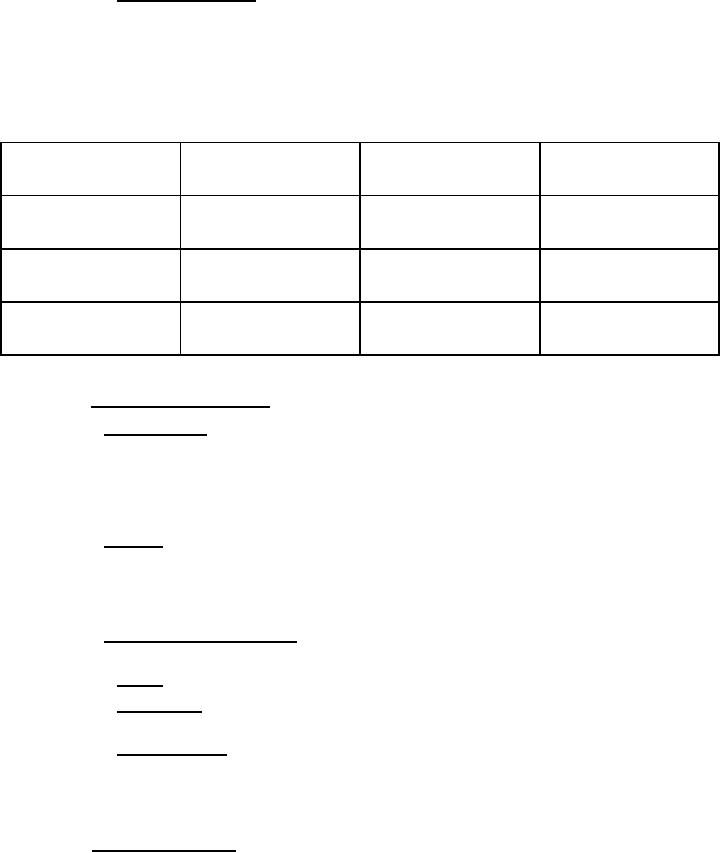

TABLE V. Sampling particulars

Sampler

Oxygen type

Method

Recommended final

pressure (gauge)

≈ 1 liter size or larger

≈12,500 kPa

I

ASTM F307

(≈ 1800 psi)

Gas Cylinder

TTU-131/E, Cosmodyne

II

ASTM F310

2750 to 3450 kPa

LLC

(400 to 500 psi)

FCS 2001, CV

II

ASTM F310

5500 to 8300 kPa

International

(800 to 1200 psi)

4.4 Cylinders of Type I oxygen.

4.4.1 Filling pressure. Containers shall be stabilized to 21°C (70°F). Containers shall be tested

for proper filling pressure by attaching a calibrated Bourdon-tube gauge or calibrated electronic equivalent

gauge to the valve outlet. The gauge shall have scale divisions not greater than 100 kPa (15 psi). Then

the valve shall be opened and the internal pressure observed on the gauge. If the internal pressure differs

from the applicable filling pressure value by more than 100 kPa (15 psi), the container, and all other

containers filled from the same manifold at the same time, shall be rejected.

4.4.2 Leakage. Each Type I oxygen container shall be tested for leaks at the neck threads, stem

packing, and safety device of the valve with leak detection fluid. Valve seat leakage shall be tested after

filling has been completed by connecting a hose to the valve outlet and placing the other end of the hose

under the surface of a liquid. Methods of leak detection and/or the leak check guidance in CGA P-15 may

also be used.

4.4.3 Inspection and maintenance. Compressed gas cylinders shall be inspected, maintained

and charged according to MIL-STD-1411.

4.4.3.1 Valves. Valves shall conform to A-A-59860.

4.4.3.2 Color coding. Government-owned cylinders shall be color coded according to

MIL-STD-101.

4.4.3.3 Identification tag. An identification tag impervious to climatic conditions shall be wired to

the outlet port of each container and shall contain the following information: Product name, specification

number with revision letter, type designation, National Stock Number (NSN), quantity, name of

manufacturer, name of contractor (if different from manufacturer), date of manufacture, and lot

identification number.

4.5 Analytical procedures. Unless otherwise specified, samples shall be analyzed according to

the procedures described in CGA G-4.3 (see 6.2). Calibration gas standards may be required to calibrate

(zero and span) analytical instruments used to determine the purity and impurity contents of the oxygen.

The accuracy of the calibration gas standards is to be traceable to the National Institute of Standards and

Technology (NIST).

7

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business